Dry Ice Blasting Services at CryoBlast Clean

Fast, Eco-Friendly Dry Ice Blasting for Automotive, Industrial, and Restoration Projects

Serving Southern California

Adhesive Removal

Asphalt Removal

Automotive Restoration

Coatings & Corrosion Removal

Coffee Roaster

Cleaning

Composite Tool

Cleaning

Core Box

Cleaning

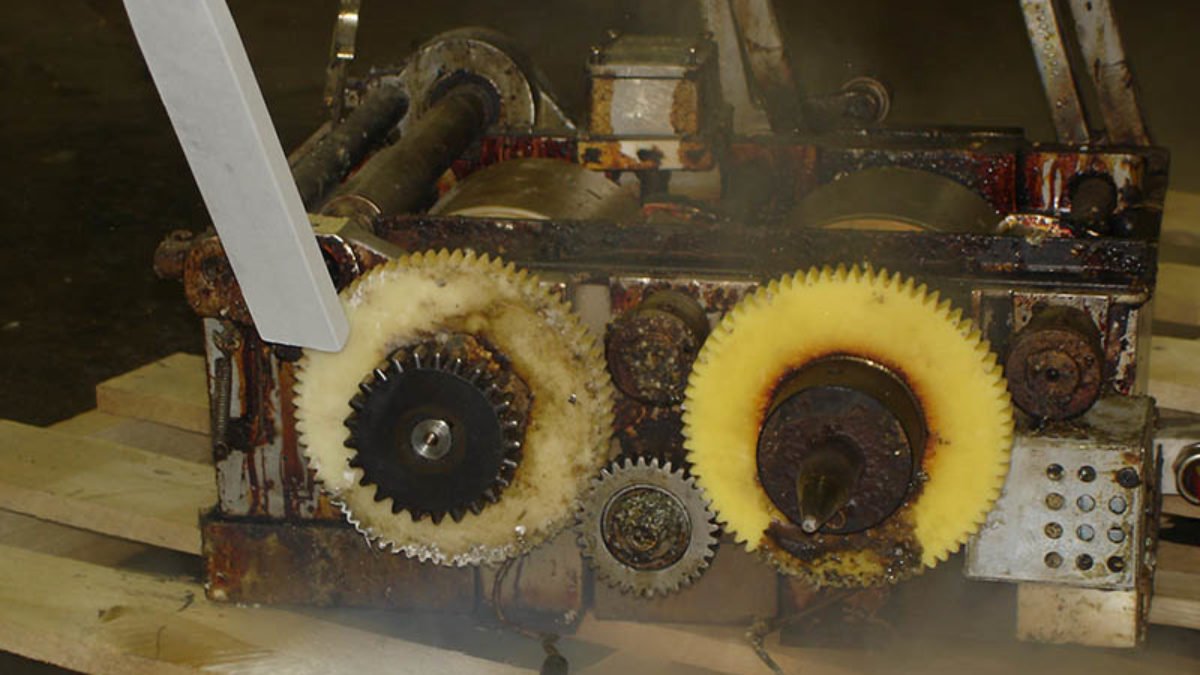

General Equipment Cleaning

Historical

Restoration

Mold Cleaning

Mold Remediation

Parts Finishing

Mold, Smoke & Water Remediation

Surface Preparation

Weld Line Cleaning

Frequently Ask Questions

Dry ice cleaning, also known as cryogenic cleaning or CO2 blasting, is a non-abrasive cleaning method that uses solid carbon dioxide (dry ice) pellets propelled by compressed air to remove contaminants from surfaces.

Yes, dry ice cleaning is an eco-friendly cleaning method because it does not produce secondary waste or harmful chemicals. The dry ice pellets sublimate upon impact, leaving behind no residue and reducing environmental impact.

Dry ice cleaning is versatile and can be used on a wide range of surfaces, including metal, wood, plastic, glass, rubber, and more. It is suitable for various industries, including automotive, food processing, manufacturing, and restoration.

Yes, dry ice cleaning is safe for delicate equipment because it is non-abrasive and non-conductive. It can effectively clean sensitive surfaces without causing damage or abrasion.

Dry ice cleaning offers several advantages over traditional cleaning methods, including reduced downtime, no use of water or chemicals, minimal waste generation, and the ability to clean in-place without disassembly. It is often faster, more effective, and environmentally friendly compared to traditional methods like sandblasting or chemical cleaning.